Ever seen a weird triangle on a metal drawing? Or maybe a V shape on a line? That’s a groove weld symbol. Looks small, right? But it’s super important!

This little mark tells welders how to join metal. It keeps things strong. Really strong.

You’ll find groove welds everywhere. In buildings. Ships. Bridges. Big machines. Without them? Stuff would fall apart. Not good!

The groove weld symbol is like a secret code. One tiny mark tells you everything. Where to weld. What shape to make. How deep to go. Pretty cool, huh?

Let’s break it down. What is this symbol thing? How do you read it? And why should you care?

What Is a Groove Weld

A groove weld joins two metal edges. Simple as that.

First, you make a gap between the edges. Like a little valley. Then you fill it with weld metal. Boom! Strong joints.

When do you use them?

• Two plates sit side by side

• Metal pieces meet at an angle

• You need to join edges end to end

Groove welds go deep. Way deeper than surface welds. That’s why big jobs use them. Think ships, pipes, and machine frames. Heavy stuff!

Why We Use Groove Weld Symbols

Drawings are how welders talk. No words needed.

Symbols show everyone what to do. The groove weld symbol tells you:

• What kind of groove (V, U, J, square)

• Which side to weld

• How deep to go

• The angle and size

• If both sides need welding

Without symbols, people would guess. Bad idea! Weak welds happen. Materials get wasted.

Symbols make sure everyone does it right. Every time. No matter where.

The Basic Groove Weld Symbol

The symbol looks simple but says a lot.

It has three main parts:

• A flat line (that’s your reference line)

• An arrow (points where to weld)

• The groove shape (like V or U)

Example:

Arrow → —V—

See that “V”? That means V-groove weld. The arrow shows where it goes.

Here’s the trick. Symbol below the line means weld the arrow side. The symbol above means welding the other side. Easy!

Common Types of Groove Welds

There are lots of groove welds. Each has its own symbol. Let’s check them out.

Square Groove Weld

Two flat edges pushed together. The symbol is just a straight line.

Use it for thin sheets or parts that fit tight.

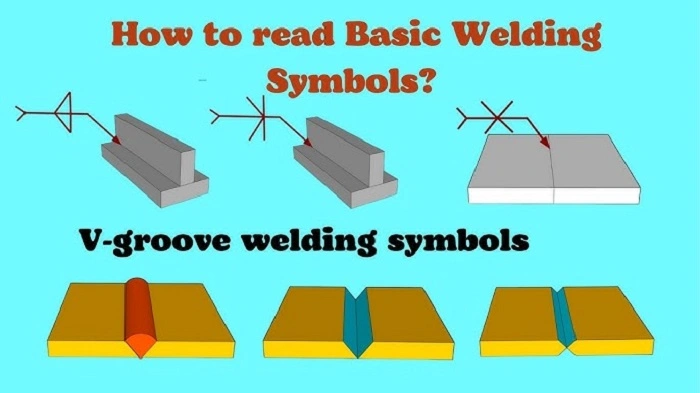

V-Groove Weld

Edges cut to make a V shape. The symbol looks like “V.”

Need a deep, strong weld? This is it.

Bevel Groove Weld

One edge is slanted, the other stays straight. The symbol shows one tilted line.

Use it when you can only prepare one side.

U-Groove Weld

Edges are curved, making a U shape. The symbol looks like “U.”

Great for thick metal. Gives smooth, deep welds.

J-Groove Weld

One edge curved, one straight. Looks like half a “U.”

Perfect when only one piece can be prepped.

Flare Groove Weld

Used between curved surfaces, like pipes or rods. The symbol is a curved line.

Made for round or tube shapes.

Each type has its job. Depends on how thick, how you can reach it, and how strong it needs to be.

How to Read the Groove Weld Symbol

A groove weld symbol packs lots of info. Here’s how to read it:

Find the arrow line. Shows where to weld.

Check where the symbol sits. Below means arrow side, above means other side.

Look at the symbol shape. Tell you the groove type.

See any numbers? Those show size, depth, and angle.

Check for extra notes like “grind smooth” or “all around.”

Example:

Arrow → —V— 6 / 60°

This means:

• V-groove weld

• 6 mm deep

• 60° groove angle

Now you’re reading like a pro.

Arrow Side and Other Side Explained

This part trips up new folks. Let me explain.

Arrow side means the side the arrow touches.

Symbol below the line means weld arrow side.

Symbol above the line means weld the other side.

Symbols on both sides mean weld both.

See? Not so hard once you know.

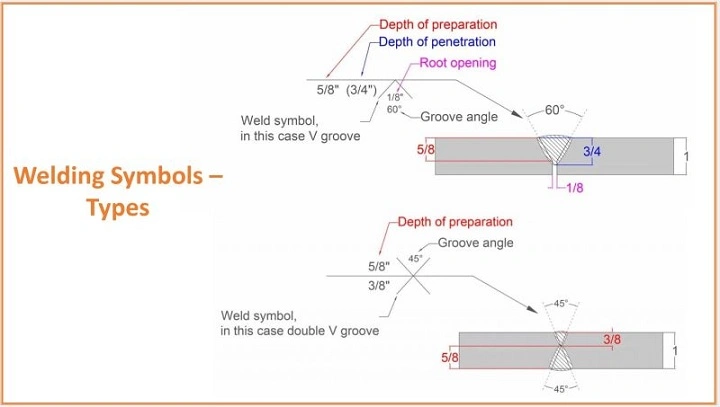

Root Opening and Groove Angle

Two key things in groove welds:

Root Opening – The gap between edges before welding. Helps weld go deep. Shows as a number like “2 mm.”

• Groove Angle – The total angle between edges. Marked near the symbol like “60°.”

Both matter a lot. Too small and the weld won’t go deep. Too big and you waste time and filler.

How to Show Weld Size and Depth

Numbers next to the symbol tell you how big and how deep.

For example:

• 8 means weld depth

• 3 means root gap

• 60° means groove angle

Full note looks like: —V— 8 / 3 / 60°

That’s an 8 mm deep V-groove with 3 mm gap and 60° angle. Simple!

Symbols for Both-Side Welds

Sometimes you weld both sides. The symbol shows groove marks above and below.

Arrow → —V—

—V—

This means welding both sides. Easy to spot.

The Tail in a Groove Weld Symbol

See that little triangle at the end? That’s the tail.

It holds extra info like:

• “MIG” or “TIG” – how to weld

• “Grind smooth” – how to finish

• “Back gouge” – remove metal for full weld

The tail catches all the details.

How Groove Welds Are Prepared

Before welding, you prep the edges. Cut or shape them to make the groove.

Common ways:

• Machine cutting

• Grinding

• Flame cutting

Good prep means good welds, less mess, and better finish. The symbol tells you exactly how.

Full Penetration vs Partial Penetration

Groove welds come in two types:

Full Penetration – Weld goes all the way through. Super strong.

• Partial Penetration – Weld goes partway. Use when full strength isn’t needed.

Drawings show this with extra lines or notes. Full might have a filled symbol. Partial shows depth numbers.

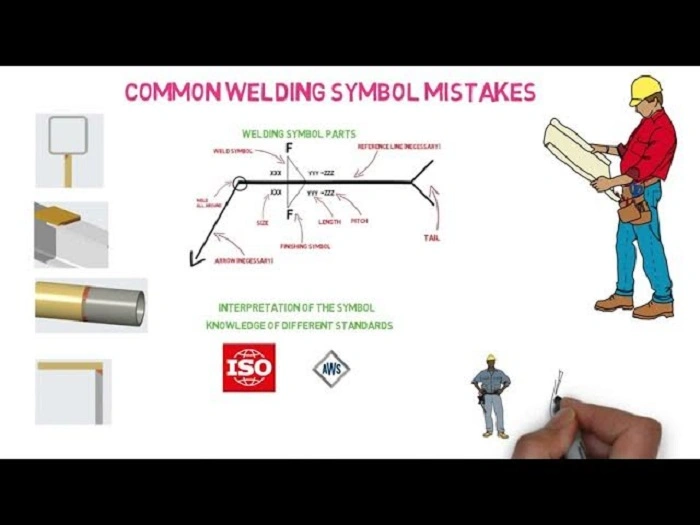

Common Mistakes When Reading Groove Weld Symbols

New folks often mess up:

• Think both sides always means double welds

• Skip the tail notes

• Forget about depth numbers

• Read angles wrong

The fix? Practice on real drawings. Do a few. The pattern clicks.

Also Read: Column Symbol: What It Is, Where You’ll See It, and How to Type It

Where Groove Welds Are Used Most

You’ll find them in:

• Bridges and buildings

• Ships and subs

• Plane frames

• Pressure tanks

• Pipelines

• Car frames

Any place where heavy metal meets edge to edge is groove weld territory.

Quality Checks for Groove Welds

Done welding? Time to test. Why? To make sure it holds.

Common tests:

• Visual check (see cracks or gaps)

• Sound test (for inside problems)

• X-ray test (for deep joints)

• Bend test (check strength)

Drawings might show test symbols too. Tells inspectors what to check.

Robots and Groove Weld Symbols

Modern shops use robots for groove welding.

Robots read the same symbols we do through computer software. Each V or U tells the robot what to do, how deep, and where to go.

Symbols work everywhere. One drawing guides hundreds of machines worldwide.

Safety and Accuracy in Groove Welding

Groove welding uses heat, power, and skill. Safety comes first.

Always wear gloves and goggles

• Clean metal before welding

• Follow the groove details exactly

One small mistake could weaken everything. That’s why symbols exist — to keep work safe and strong.

Groove Weld Symbol vs Fillet Weld Symbol

People mix these up. Here’s the difference:

Groove weld joins edges

• Fillet weld joins corners

The Groove symbol uses V or U shapes. The fillet symbol looks like a triangle. Both are common but for different uses.

Open edges mean groove. Corner or T-joint means fillet.

Why Groove Weld Symbols Matter

These symbols bring order to big jobs. They save time, stop mistakes, and make things strong.

A tiny mark on paper controls tons of steel in real life.

Every bridge starts with a drawing. Every ship. Every pipeline. And those drawings start with symbols.

The groove weld symbol is more than a mark. It’s a guide that helps welders build safe stuff, strong stuff, stuff that lasts.

It tells where to weld, how deep, and what shape. Whether it’s V, U, J, or bevel, the meaning stays clear.

Next time you see one, you’ll know what it means. It’s how welders talk, clear, smart, and simple.

Pretty cool for a little symbol, right?