Ever see a metal drawing? Notice those tiny circles near weld lines? That’s the spot weld symbol. Looks simple, right? But it tells you lots.

Spot welding is huge. Cars use it. Metal shops too. Even your phone has spot welds. It joins thin metal fast. Real fast. The symbol? It tells welders where to work. How to work. All in one tiny mark.

Let’s dig in. What’s this symbol mean? How do you read it? Why’s it matter so much?

What’s Spot Welding?

Spot welding joins metal sheets. Uses heat. Uses pressure. But here’s the cool part, it only melts one tiny spot. Not the whole thing.

Here’s how:

• Two copper tips press the metal

• Power flows through

• Metal melts at that spot

• Pressure holds it tight

• It cools and sticks

That melted bit? We call it a “weld nugget.” Small but strong. Super strong.

You’ll find spot welds in cars. Planes too. Even your kitchen stuff.

Why We Need These Symbols

Think about it. Welders work all over. They need to know what to do. Same info. Same results. That’s why we use symbols.

The spot weld symbol shows:

• What kind of weld

• Where to put it

• How many spots

• How big

• Which side

No long notes. Just one mark. Everyone gets it.

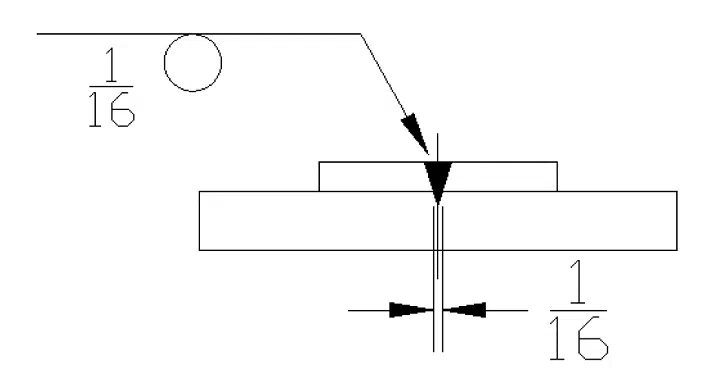

The Basic Symbol

The spot weld symbol? Dead simple. It’s a circle on a line.

Like this:

—◯—

That circle? That’s your spot. The line? That’s your guide.

Circle below the line? Weld the arrow side.

Circle above? Weld the other side.

Both? Weld both sides.

Easy, yeah? But wait. There’s more.

That Guide Line

Every weld symbol starts here. The guide line. Think of it like a home base.

It has:

• An arrow (shows where to weld)

• The symbol (shows how to weld)

• Extra notes (if needed)

The arrow points to your joint. Where does it touch? That’s the arrow side. The other side? Well, that’s the other side.

See where the circle sits? That tells you which side needs work.

Circle = Spot

That little circle means one weld spot. But what if you need more? Numbers tell you.

Like this:

—◯— 50

That “50”? Spots are 50 mm apart.

Sometimes you see two numbers:

—◯— 5 / 50

First number (5)? Spot size.

Second (50)? Space between.

It’s like a short code. Quick to read.

Where We Use Spot Welds

Spot welding rocks. It’s fast. Cheap too. No extra rods needed.

You’ll find it in:

• Car bodies

• Plane wings

• Metal chairs

• Electric boxes

• Pots and pans

• Battery tabs

Got thin metal? Spot weld it. The symbol makes sure every joint matches. No mess-ups.

Reading Symbols Step by Step

Want to read one? Here’s how:

Step 1: Find the main line.

That’s your guide line.

Step 2: Look for the arrow.

Shows you where to weld.

Step 3: Check the circle.

• Below = arrow side

• Above = other side

• Both = both sides

Step 4: Read the numbers.

They show size. Or spacing.

Step 5: Check for notes.

Maybe there’s extra info.

Done! Now you can read spot weld symbols.

What Each Part Means

A full symbol has parts:

Arrow – Points to the joint

Line – Holds the symbol

Circle – Says “spot weld”

Numbers – Size and space

Tail – Extra notes (maybe)

Here’s one:

Arrow → —◯— 6 / 40 (DC)

This means:

• Spot weld, 6 mm wide

• 40 mm apart

• Use DC power

Different Spot Patterns

Spots can go many ways.

- Single: One weld. Two sheets.

• Line: Spots in a row.

• Many: Lots of spots around.

• Side by side: Spots next to each other.

The symbol shows how to space them. Make them even.

Size and Space Matter

Size is key. It affects strength. Heat too. Time as well.

Rule of thumb? Spot size = 3 times sheet thickness.

Like: 1 mm sheet = 3 mm spot.

Space matters too. Too close? Metal gets too hot. Too far? The joint gets weak. That’s why we mark it clearly.

Cars and Planes Love Spot Welds

Cars? They’re full of spot welds. One car might have 5,000 spots. Wow!

Engineers use symbols to place each one. Perfect spots. Every time. Cars need strong joints. So do planes. One bad weld? Big problem.

Symbols keep it standard. Any welder. Any place. Same results.

Also Read: Merchant Navy Symbol Explained: Meaning, History, and What It Stands For

Extra Notes You Might See

Sometimes symbols have codes:

- AC or DC – Power type

• Nugget size – Exact weld width

• Electrode type – Which tip to use

• Pressure – How hard to press

These go near the symbol. Help welders pick the right settings.

Spot Welds vs Other Types

Spot welding is just one type. Others have symbols too:

- Fillet: Triangle shape

• Plug: Filled circle

• Seam: Line with circle at end

• Projection: Circle with crosses

Spot weld? Just an open circle. Easy to spot. (Get it?)

Checking the Work

After welding? Time to check. Some drawings show test symbols.

See a check mark? That means “test this weld.” Other marks might mean sound tests. Or visual checks.

These make sure welds are strong. Safe too.

Why Symbols Matter So Much

No clear symbols? Workers might guess. Wrong size. Wrong spot. That’s bad news. Could mean weak joints. Or worse.

Symbols help us:

• Save time talking

• Keep quality same

• Make less mistakes

• Stay safe and strong

It’s like a map. Simple map. But it works great.

Robots Use Symbols Too

Modern shops? They use robot arms. These robots read digital drawings. Same symbols guide them.

Each circle becomes a weld point. Robot presses. Welds. Moves. Repeat. All day long.

Clear symbols matter more now. Machines need them too.

Stay Safe

Spot welding looks easy. But it’s hot. Uses lots of power. Symbols show where. Safety keeps you whole.

Tips:

• Wear gloves

• Use goggles

• Keep tips clean

• Stay dry

• Use right pressure

The symbol guides. Safety protects.

What’s Next?

Welding goes digital now. CAD programs add symbols. Click click. Engineers test strength before building.

But that circle? Still the same. Paper or screen. Still tells welders what to do.

That tiny spot weld symbol? It’s huge. Shows how metal joins. Safe joins. Strong joins.

A circle on a line tells everything, where, how big, how far, which side.

From old-school welders to new robots. All follow that mark. That’s what makes it great. It’s the quiet language of metal work.

Next time you see that circle? Remember. It’s not just a shape. It’s a guide. A link. The mark of good work.